- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

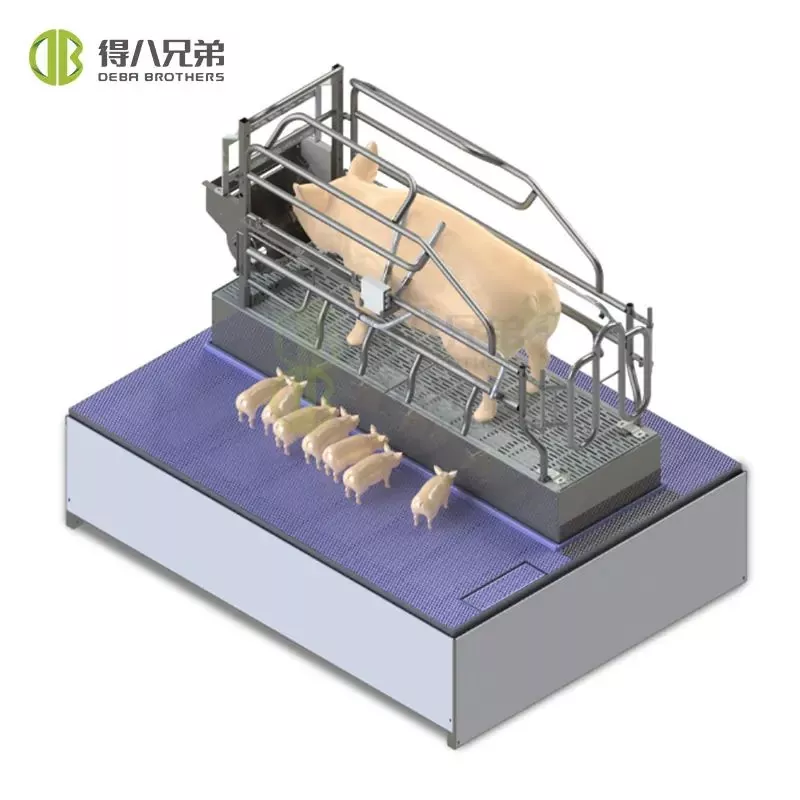

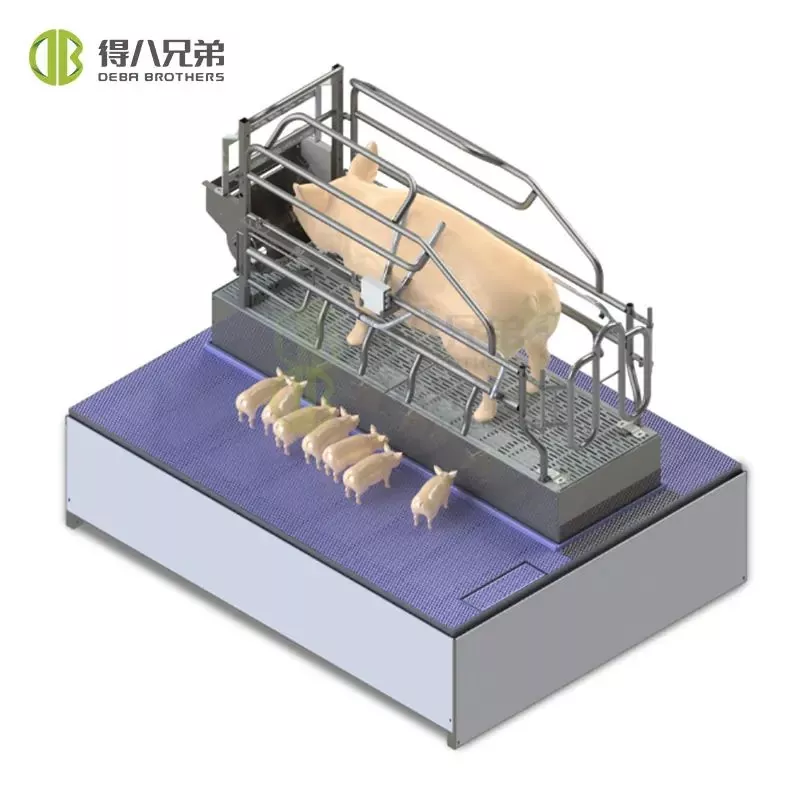

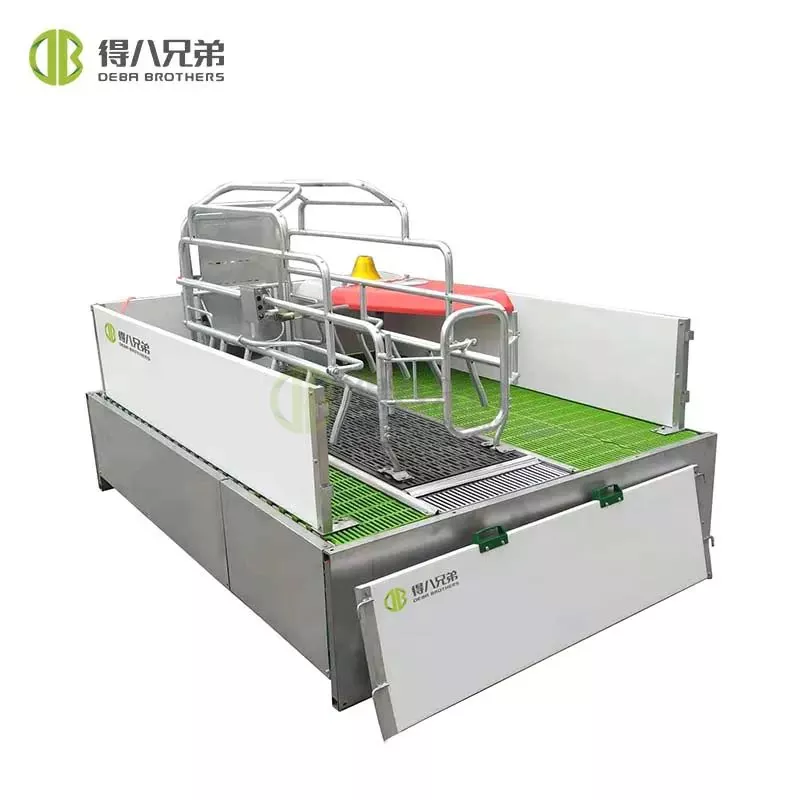

Lift Farrowing Crate

Deba Brothers® is a professional China Lift Farrowing Crate manufacturers and suppliers. Lift farrowing crate can reduce the mortality of piglets effectively and provide a basic guarantee for PSY. When the sow stands up, the back of the sow touches the sensor and raises the sow’s position through the pressure system. In the process, the piglet will leave the sow lift. When the sow lies down, the stall sensor is turned off, and after the sow’s position slowly drops to a uniform level, the piglets can continue to eat. The elevator farrowing crate can reduce the chance of the piglets being crushed.

Send Inquiry PDF DownLoad

Deba Brothers® is a leading China Lift Farrowing Crate manufacturers, suppliers and exporter. The lift farrowing crate is a kind of farrowing crate specially produced by Deba Brothers® to protect piglets. Lift farrowing crate can reduce the mortality of piglets from 5% reduce to lower than 1%, prevent the sow from rolling on and crushing her piglets, especially the first week after the piglet born, and provide good performance PSY. When the sow stand up, the sow back touches the sensor and raises the sow’s standard floor through the compress air system, the piglet will leave the sow’s floor then. When the sow lies down in the lift farrowing crate, the sensor don’t touch sow’s back and lift floor drops slowly to ground floor level, the sow can continue lactation the piglets.

Lift Farrowing Crate Specifications

|

Total size |

2400*1800mm |

|

Stretch trough |

500*420*290mm,SST 304,1.5mm thickness |

|

Sow floor |

25’*42’America cast iron floor/tri-bar floor |

|

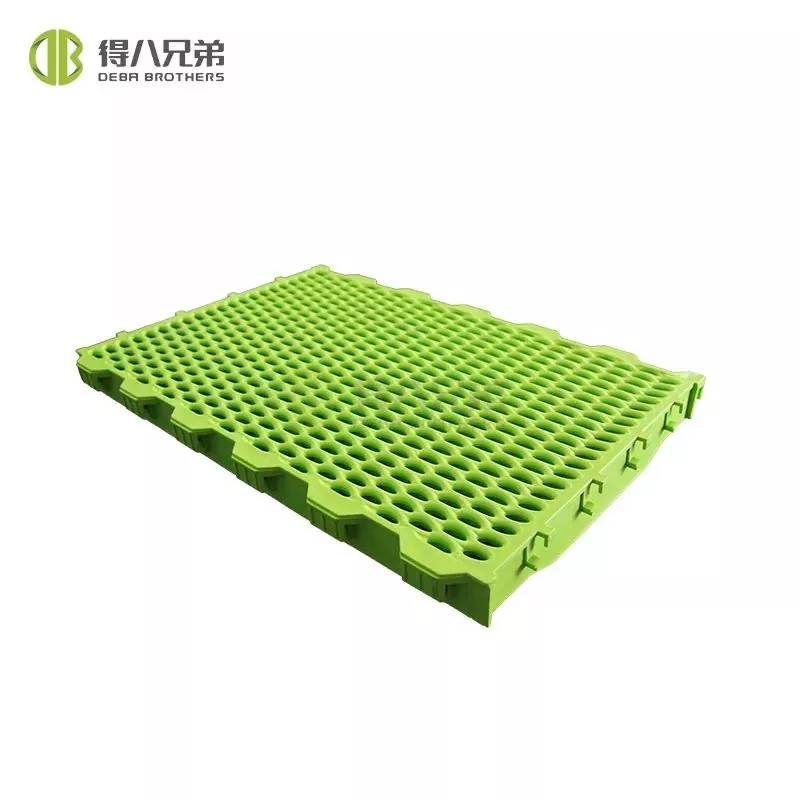

Piglet floor |

400*600 plastic floor lift |

|

Support beam |

2400*120mm galvanized steel beam&FRP beam |

|

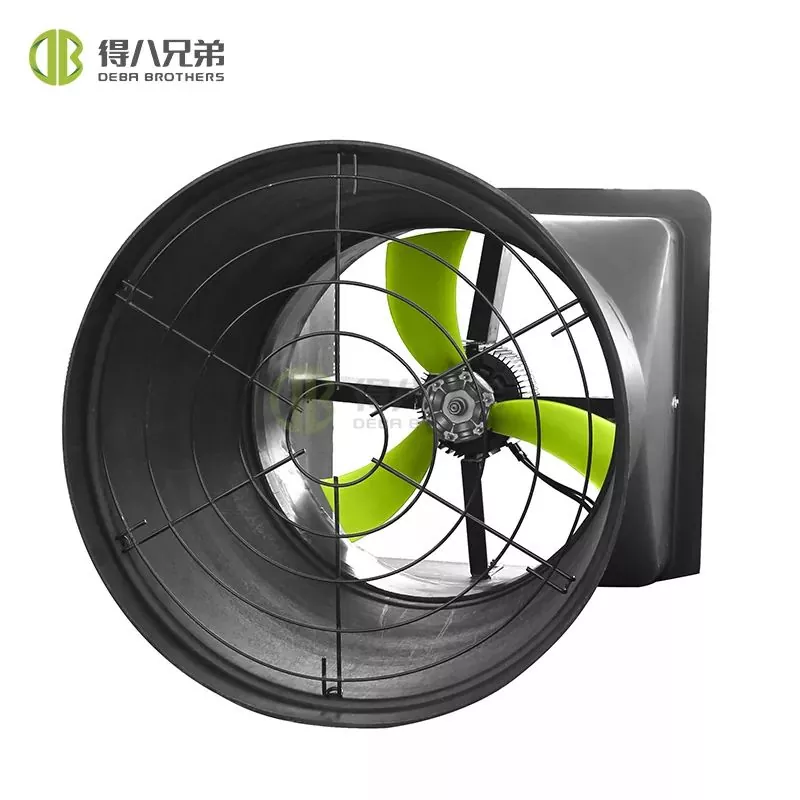

Insulation system |

Triangle plastic insulation box&175W insulation lamp |

Lift Farrowing Crate Accessories

|

Stainless steel rolling feeder |

wholly turn round |

|

Sensor |

Measure feed volume left in feeder |

|

Stainless steel lifting platform |

Separate sow and piglet; prevent the piglet to be crushed |

|

Fully plastic coated steel floor |

non-slip and does not hurt the hoof |

|

304 stainless steel+plastic lifting move device |

antirust and easy to clean |

|

Removable hot dip galvanized rear door |

adjustable space |

|

Wholly hot dip galvanized steel stall |

20 years anti-rust |

Lift Farrowing Crate Advantage

1.The crushed piglet rate is reduced by 90%, and the adjustable farrowing pen equipment cost is recovered in one year.

2.Directly reduce 1-2 piglets to be crushed to death per litter.

3.Comprehensively improve PSY, each lactation period can be reduced. There is no need for personnel to supervise the production process by using balance farrowing pen.

Lift Farrowing Crate details

1.The height of elevated platform is 25cm, and there is an prevent pinching strip.

2.Sensor,touch sow back to control lift up and down.

3.Stainless steel stretch feeder, rolling turn round.

4.Free choice of plastic-coated floor and plastic floor to control costs.