- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Pig Farm Auger Systems

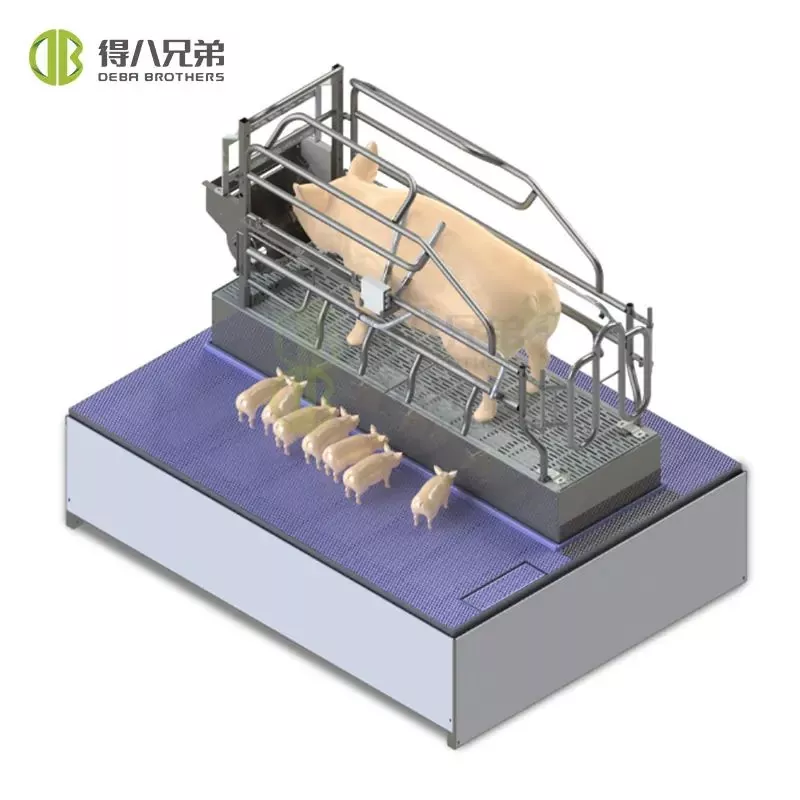

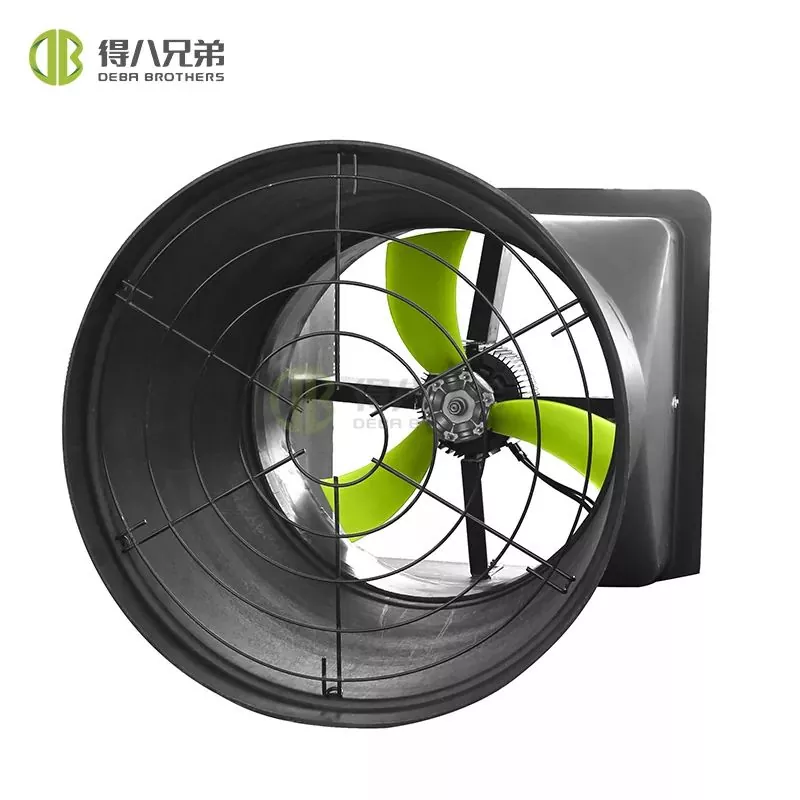

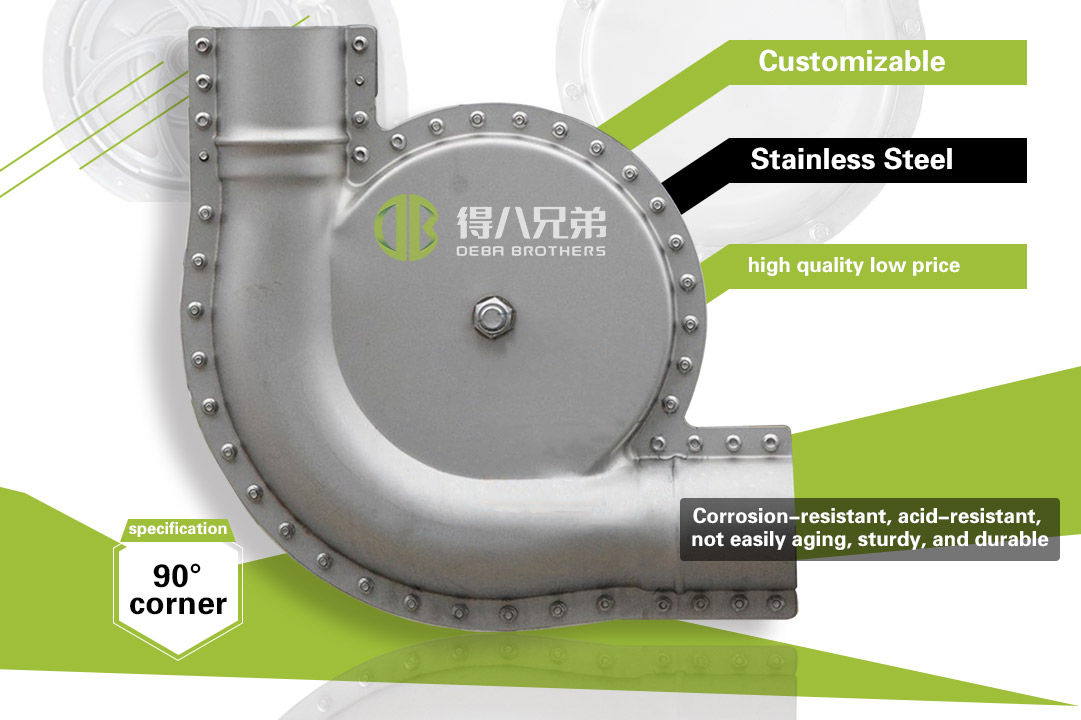

Deba Brothers® is a leading China Pig Farm Auger Systems manufacturers. Dry feeding system include two different type system such as chain system and auger system.Pig auger auto feeding system named dry feeding system,we would give you our suggestion according to your pig farm.You can choose different sizes of pipe line and the driving unit to adapt to the different feeding volume.Normal service life is up 10 to 15 years.

Send Inquiry PDF DownLoad

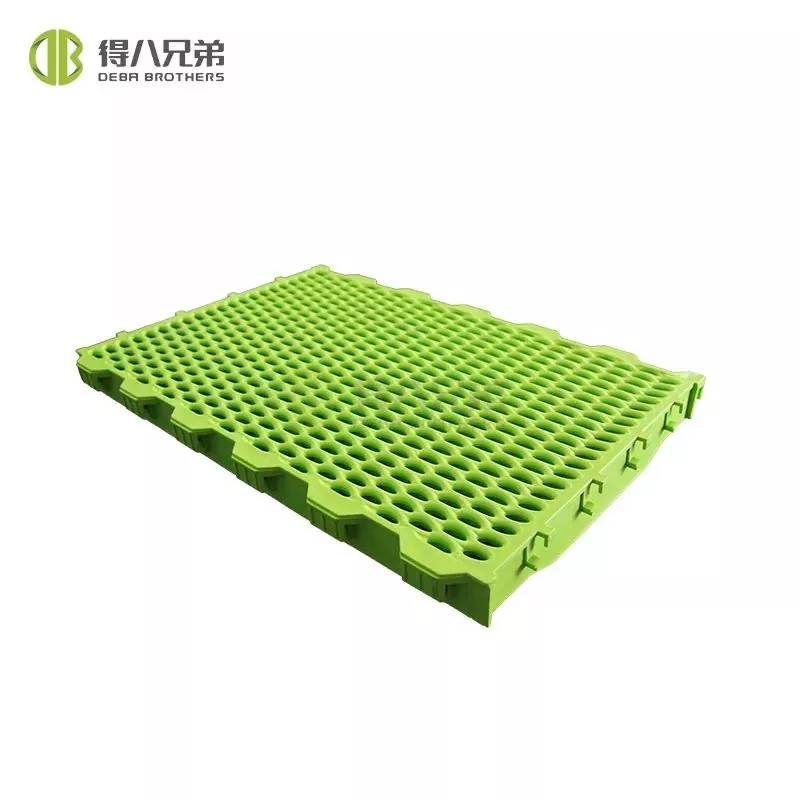

The pig farm auger systems is one of the feeding systems produced by Deba Brothers® in China. Your feed – be it meal, pellets or crumbles – passes from the silo into the house safely and without any loss of quality. The pig farm auger systems range includes spirals, augers and conveyor chains of different sizes. The pig farm auger systems are the ideal option. Conveyor chains should be selected for very long conveying lengths and complicated building layouts.

Pig Farm Auger Systems Specifications

|

Item |

Pig automatic feeding part |

|

Size |

It’s can be design based on your farm |

|

Advantage |

Automatic equipment/Saving labor |

|

Packing |

By carton on non-woven bag |

|

Deliver |

20-30 days after the deposit |

Pig Farm Auger Systems Accessories

|

Silo |

2.6T/4.2T/5T/8T/10.4T/14.1T/19T/25.2T/31.3T |

|

Main engine |

1.5kw/2.2kw |

|

Electric control box |

Auger feed |

|

Auger |

Outer diameter:45.5/60.5/75mm Inner diameter:24.5/36.5/47mm Screw pitch:45/60/53mm |

|

Quantitative tube |

5L/6L |

Pig Farm Auger Systems Advantage

1. Achieved automatic with feeding and data system statistics.

2.One breeder can feed 600 to 1200 heads sow. (For high bed no cleaning dung pig housing)

3.Save more than 50% labor wages, only need 1 minutes can finish the feed for 300 heads sows.

4.Increase more than 90% feeding frequency.automatic pig feeding system can fill 1,500 kg forge per hour.

5.Labours saved and cost reduced due to computer control system adopted

6.The adjustable transparent dispenser has 0.25kg to 3kg gears, which controls the weight of the pregnancy sow effect.