- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

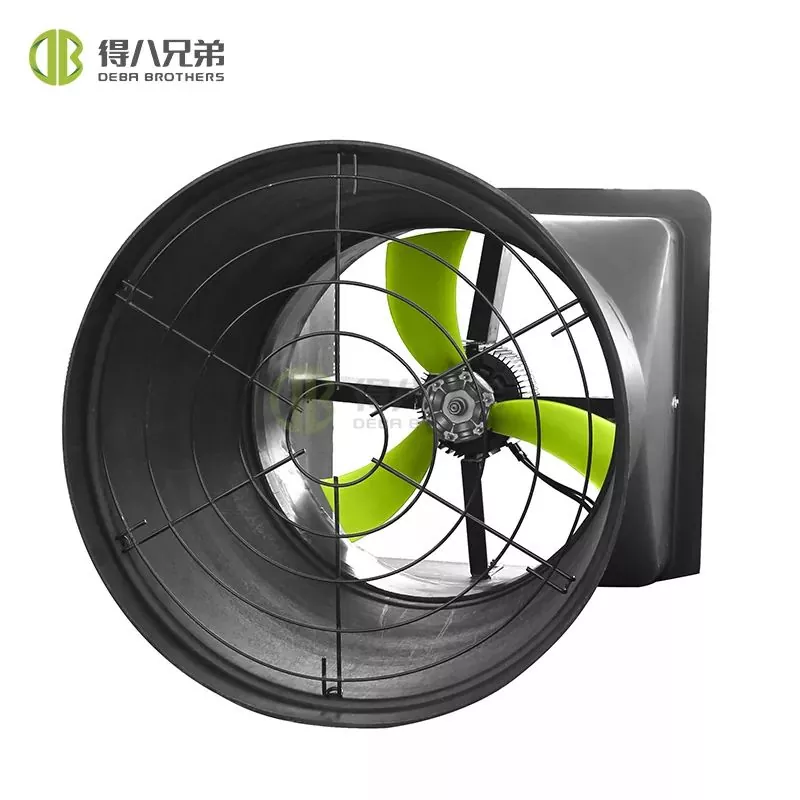

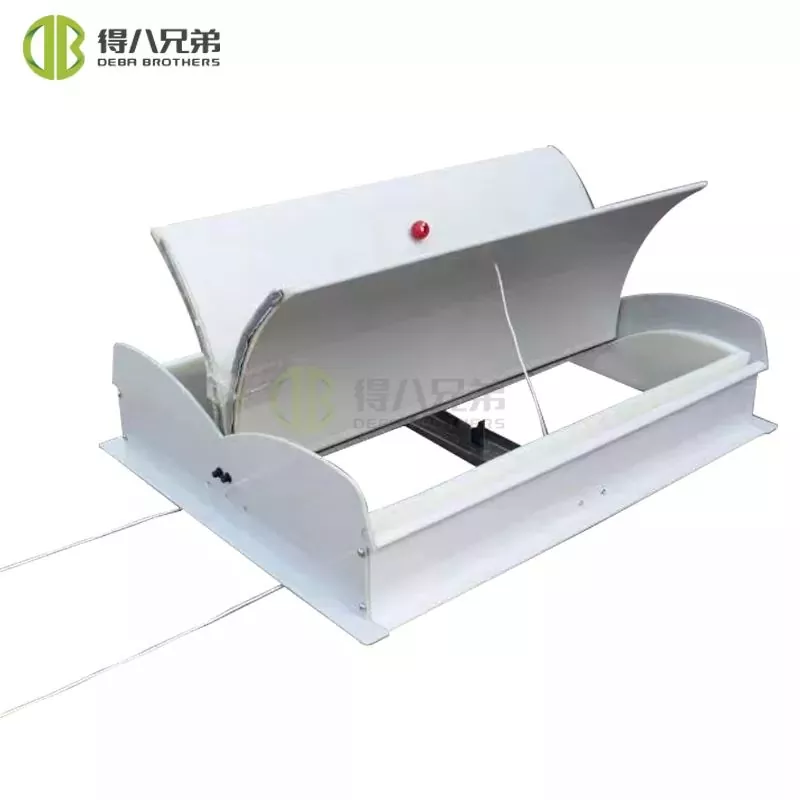

Pig Fan with AC Motor

Deba Brothers® is a professional leader China Pig Fan with AC Motor manufacturers with high quality and reasonable price. Fan blades are special designed for the biggest efficiency which made of Krupp stainless steel by punch forming. Large air volume, no deformation, no broken, no dust, attractive and durable.

Send Inquiry PDF DownLoad

As the professional manufacturers, Deba Brothers® would like to provide you Pig Fan with AC Motor. If there is heating equipment, there should be ventilation equipment, so Deba brothers® developed pig fan with AC motor. Pig fan with AC motors are perfect for installation in the wall, especially in smaller barns and when using cross ventilation. Compared with pig fan with EC motor, pig fan with AC motor has low cost and small air volume, and is also very suitable for poultry houses.

Pig Fan with AC Motor Accessions

|

Fan name |

Power |

Static Pressure |

Pa |

0 |

12 |

25 |

37 |

50 |

62 |

installation open (mm) |

|

In.H2O |

0 |

0.05 |

0.1 |

0.15 |

0.2 |

0.25 |

||||

|

54’’ |

1.5KW |

capacity |

m3/h |

57950 |

54260 |

51150 |

47280 |

43140 |

38870 |

H:1540 W:1490 |

|

cfm |

34060 |

31880 |

30060 |

27765 |

25350 |

22825 |

||||

|

energy efficiency ratio |

m3/h/w |

31.2 |

27.7 |

25.3 |

22.9 |

19.2 |

16.5 |

|||

|

cfm/w |

18.4 |

16.3 |

14.9 |

13.5 |

11.3 |

9.7 |

||||

|

51’’ |

1.1KW |

capacity |

m3/h |

48580 |

46110 |

42760 |

39110 |

34820 |

29770 |

H:1470 W:1440 |

|

cfm |

27125 |

25150 |

23005 |

23005 |

20480 |

17470 |

||||

|

energy efficiency ratio |

m3/h/w |

36.9 |

33.6 |

30.5 |

27.1 |

23.9 |

20.1 |

|||

|

cfm/w |

21.7 |

19.8 |

17.9 |

15.9 |

14.1 |

11.8 |

||||

|

50’’ |

1.1KW |

capacity |

m3/h |

45600 |

42910 |

39430 |

35200 |

29180 |

16750 |

H:1390 W:1390 |

|

cfm |

26825 |

25240 |

23195 |

20705 |

17165 |

9855 |

||||

|

energy efficiency ratio |

m3/h/w |

32.1 |

30.3 |

28.7 |

26.5 |

24.4 |

20.2 |

|||

|

cfm/w |

18.9 |

16.9 |

17.8 |

15.6 |

14.4 |

11.9 |

||||

|

36’’ |

0.75KW |

capacity |

m3/h |

23860 |

22375 |

20690 |

19530 |

17680 |

15930 |

H:1090 W:1090 |

|

cfm |

14035 |

13160 |

12170 |

11490 |

10400 |

9370 |

||||

|

energy efficiency ratio |

m3/h/w |

25.6 |

23.3 |

21 |

19.3 |

17.3 |

15.4 |

|||

|

cfm/w |

15.1 |

13.7 |

12.4 |

11.4 |

10.2 |

9.1 |

||||

|

24’’ |

0.30KW |

capacity |

m3/h |

12850 |

11790 |

10970 |

9860 |

8930 |

6120 |

H:790 W:790 |

|

cfm |

7560 |

6940 |

6455 |

5800 |

5255 |

3600 |

||||

|

energy efficiency ratio |

m3/h/w |

24.3 |

22.4 |

21.0 |

19.3 |

17.3 |

15.4 |

|||

|

cfm/w |

14.3 |

13.2 |

12.4 |

11.4 |

10.2 |

9.1 |

||||

|

18’’ |

0.15KW |

capacity |

m3/h |

7900 |

7640 |

7020 |

6450 |

4980 |

|

H:580 H:580 |

|

cfm |

4645 |

4495 |

4310 |

3795 |

2930 |

|

||||

|

energy efficiency ratio |

m3/h/w |

28.5 |

25.6 |

18.5 |

15.9 |

13.1 |

|

|||

|

cfm/w |

16.8 |

15.1 |

10.9 |

9.4 |

7.7 |

|

Pig Fan with AC Motor Advantage

1.The fasteners of centrifugal system all are copper rivets, wear-resisting and no rust, flexible. Guide rod is made of 304 stainless steel, ensure the high strength, no rust, reduce friction.

2.Ensure the long service life, maintenance free.

3.Fan belt pulley and flange are made of high strength aluminum-magnesium alloy by die-casting. Light weight, lower vibration.

4.Linking parts are made of aluminum alloy,light weight,no deformation,added with wear-resistant shaft sleeve.

5.Standard parts especially the washer as fastener parts are made of stainless steel, no rust, beautiful appearance.

6.High strength, low noise, free maintenance and long service life.

Pig Fan with AC Motor details

1.Integra I molded fiberglass reinforced shell;

2.Low wind resistance;

3.High energy efficiency;