- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

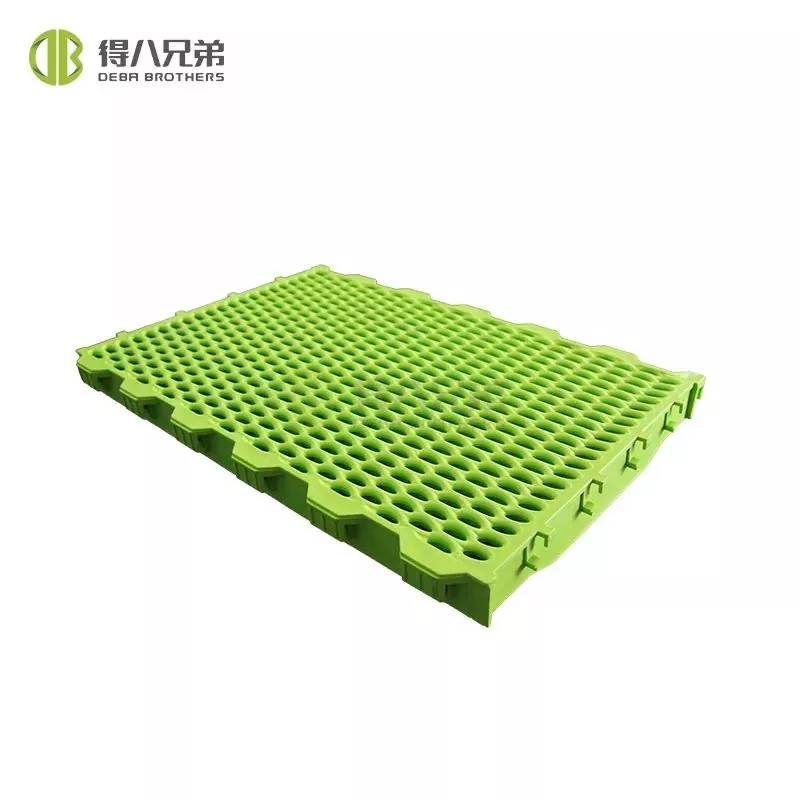

Deodorization Plastic Wet Curtain

DEODORIZATION PLASTIC WET CURTAINS are revolutionizing livestock farming by providing a cutting-edge solution for odor control and ammonia removal. These curtains, made from eco-friendly materials, offer high-efficiency deodorization while maintaining a clean and sustainable farm environment. Say goodbye to unpleasant odors and hello to a breath of fresh air for your livestock.

Send Inquiry

1. Rapid Diffusion:

One of the standout features of DEODORIZATION PLASTIC WET CURTAINS is their ability to facilitate rapid odor diffusion. This is crucial in achieving

effective deodorization quickly and efficiently.

2. Long Efficiency:

Unlike traditional paper-based wet curtains, which often lose their effectiveness over time, plastic curtains maintain their efficiency for extended periods.

This ensures a consistently clean and odor-free environment for livestock.

3. Environmentally Friendly:

DEODORIZATION PLASTIC WET CURTAINS are eco-friendly, containing no allergenic substances. They align with green and sustainable farming

practices while offering economic benefits to farmers.

4. Easy Maintenance:

Cleaning and maintaining these plastic curtains is a breeze. High-pressure cleaning can be applied without worrying about deformation,

and this ease of maintenance contributes to their extended service life.

5. Customizable:

Farmers can customize the size of these curtains to suit their specific needs, ensuring a tailored approach to deodorization.

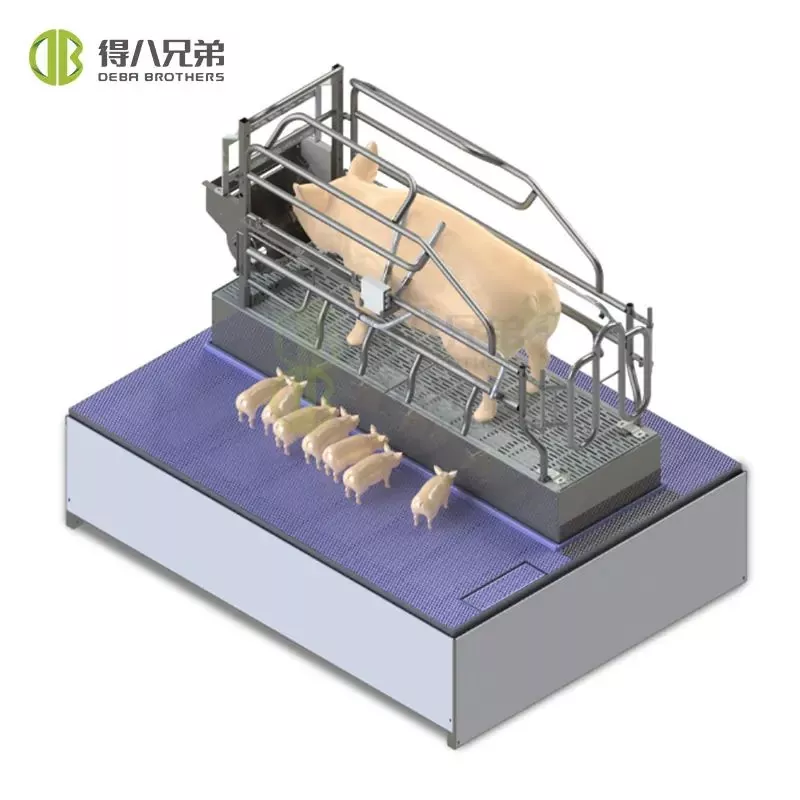

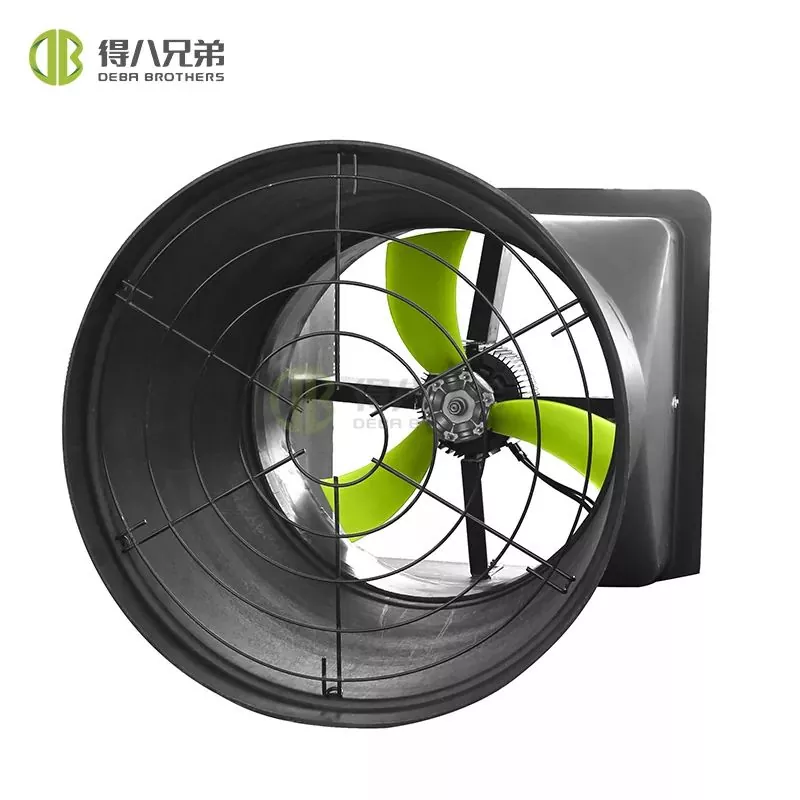

The "Livestock House Purification and Deodorization System" represents a revolutionary approach to intensive air purification for livestock breeding.

This system efficiently tackles odors using a combination of chemical and biological purification methods, tailored to the specific requirements of different

farm areas. For pig farms, the deodorization system is composed of a deodorization filter block, a circulating spray, water treatment, and intelligent

control systems. It boasts an impressive track record, with an ammonia removal rate of 70-95%, hydrogen sulfide and other odor removal rates

ranging from 40-75%, and dust removal rates spanning 45-80%. What sets this deodorization system apart is its modular design,

enabling quick and easy on-site installation.

FAQ:

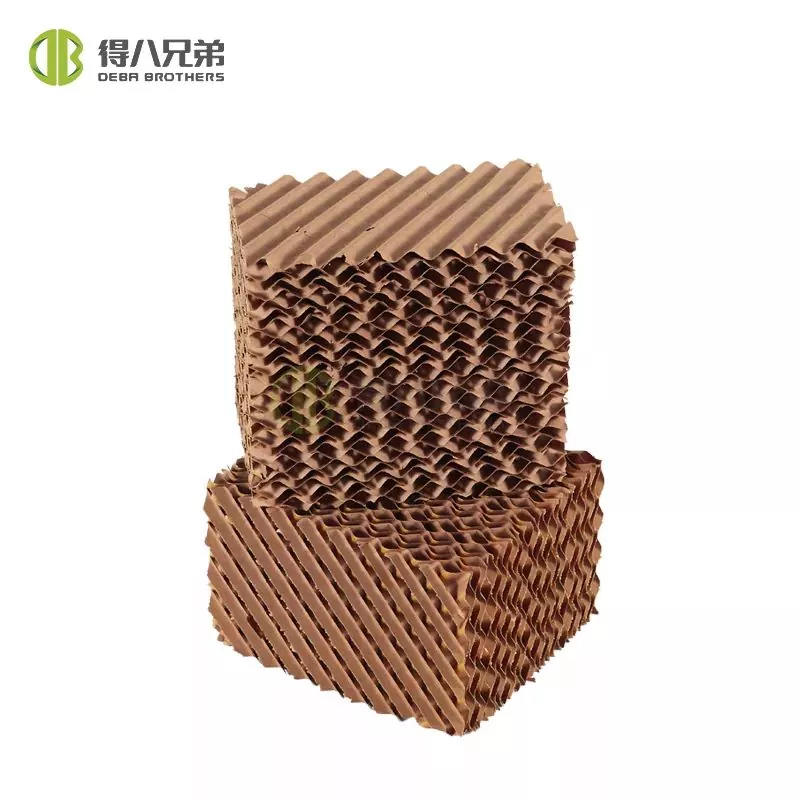

1. What is the function of the odor-removing plastic wet curtain in livestock farming?

Answer: The odor-removing plastic wet curtain plays a critical role in enhancing the overall purification process of the revolutionary odor-removing

system in livestock farming. The wet curtain is made of high-quality plastic materials and helps remove unpleasant smells in the air.

2. How does the odor-removing system work in livestock farming?

Answer: The odor-removing system in livestock farming combines chemical and biological purification methods to address odor issues effectively,

depending on specific requirements in different farm areas. It comprises odor-removing filter blocks, circulating spray, water treatment,

and intelligent control systems.

3. Can the odor-removing plastic wet curtain be installed easily on site?

Answer: Yes, the odor-removing plastic wet curtain is designed in a modular way to enable quick and easy on-site installation. The system's unique

modular design facilitates the installation process.

4. What is the removal rate of NH3 in the odor-removing system?

Answer: The removal rate of NH3 in the odor-removing system can reach up to 85%, making it an effective solution for addressing odor issues

in livestock farming.

5. What is the significance of the odor-removing system in livestock farming?

Answer: The odor-removing system in livestock farming marks a revolutionary method for improving livestock farming environments, creating

a comfortable and healthy living environment for cows, pigs, and other animals. It also helps reduce environmental pollution and increase productivity.